MOU Details

|

Sl. No. |

Name of the Company |

From |

To |

|

1 |

MSPL Limited |

18.03.2024 |

Perpetual |

|

2 |

Bhoruka Power Corporation Limited |

01.03.2024 |

Perpetual |

|

3 |

Bangalore Electricity Supply Company Limited (BESCOM) |

06.09.2003 |

Perpetual |

|

4 |

Mysore Electrical Industrial Limited (MEI) |

12.10.2023 |

Perpetual |

|

5 |

SMPS Electric Control Private Limited, Odisha |

23.12.2022 |

22.12.2024 |

|

6 |

Log9 Materials Scientific Private Limited |

26.12.2022 |

25.12.2025 |

|

7 |

Bhoruka Power Corporation Limited |

23.11.2022 |

Perpetual |

|

8 |

Karnataka Renewable Energy Development Limited |

16.11.2022 |

Perpetual |

|

9 |

Bullwork Mobility Pvt Ltd, Bengaluru |

23.05.2022 |

Perpetual |

|

10 |

SELCO Foundation, Bengaluru. |

25.05.2022 |

24.05.2023 |

|

11 |

Vidyut Kanti Engineering Services, Bengaluru |

06.04.2022 |

Perpetual |

|

12 |

Xircular Pvt Ltd, Bengaluru |

06.09.2021 |

Perpetual |

|

13 |

SkillDzire Technologies Pvt Ltd |

04.11.2020 |

03.11.2023 |

|

14 |

GIZ & Skill Council for Green Jobs(SCGJ), Delhi |

03.08.2020 |

30.05.2022 |

|

15 |

Greaves Cotton Limited, Bengaluru |

11.01.2020 |

Perpetual |

|

16 |

Karnataka Veterinary Animal and Fisheries Science University, Bidar, Karnataka. |

20.08.2019 |

20.08.2029 |

|

17 |

LAPP Cable India, Bengaluru |

16.01.2019 |

Perpetual |

Industry Sponsored Labs

Power and Automation Technologies Laboratory (ABB Lab)

LAPP CABLE LAB

Signed and MoU with LAPP CABLE – Germany for setting up a lab, Renewed on (16th Jan 2019). They have invested to a tune of 15 lacs on the equipment where students are being trained on various methods of testing electrical cable. Plans to introduce a course on cables as an elective.

The experiments are beyond the syllabus, listed below:

- HV Test

- AC voltage withstand test

- DC voltage withstand test

- Heat shock test on LV cable

- Shrinkage test

- Dimension Measurement using profile projector ,

- Tensile strength of the conductor

- Measurement of Resistance

- Thermal Ageing studies on cables

- Flammability Test

- Loss of Mass

The laboratory equipments include

- CR meter fully automated with bridge

- Digital Cr meter without temp. compensation bridge

- Conventional CR meter with galvanometer, volt source and bridge

- Water bath for routine HV / IR, VR test

- Hot Air oven

- 1 cell ageing overn

- Air compressor 0.5 Hp

- Weighing balance 0-5 kg with 1 gm accuracy

- Hot deformation tester

- Flammability tester

- Dumble die

- Dumble cutter

- Hydraulic Press

- AC HV tester 0-10KV

- DC HV tester 0-1.5 KV

- Megger

- Temsile strength testing equipment

- Hot set test apparatus

- Vacuum oven

- Million megohm meter

- Smoke density tester

- Annealing tester

- Profile projector

Centre of Excellence in e-Mobility:

RVCE has an MoU with Greaves Cotton Limited, signed on 11th Feb 2020. They have sponsored five 2 wheelers and given accessories for the Lab.

Lab is equipped with high end computers and related software for students to do their project .

Objectives

Details of Activities under this MOU

-

Internship and Final Year Projects

-

Campus recruitment referred through placement

-

Training Program

-

Short Term Consultancy projects

-

Long Term R & D Projects

-

Business Model Development

-

Guest Lectures

-

Curriculum Design

Competence Development :

GCL would create competence in RVCE through its Internship and training Exchange program in the following areas :

- Electric vehicle Design

- Electric vehicle Architecture

- Functional Safety in Electric vehicles through ISO26262

- Vehicle Styling and Industrial Design

- Sub Systems Design like Controller, Motor, Battery Systems, Regenerative Braking, Connected Vehicles etc.

- Verification and Validation of Sub Systems and Reliability Engineering

- Concepts of HALT, HAST and MEOST in Accelerated testing.

- EMI/EMC of sub systems and Vehicles

Projects to be done Together:

During the 1styear of the ‘COEEM’ – GCL and RVCE would work on following projects :

i. Controller Design for 1.2 kw and 3 kw BLDC Traction Motors

ii. BMS Design for Lion battery

iii. CAN Based telematics Gateway Unit for Preventive Diagnostics

iv. Application Software for Special Features in EV’s – IP shared by RVCE and GCL

v. Research in developing Hybrid battery solution with Ultra Capacitors

Ways of Working :

i. Interns would be taken every year at Undergraduate and Postgraduate levels from all streams including ME, EEE, E&C, CS and E&I

ii. The Interns would work between Jan~May and would use the infrastructure and software and hardware of both GCL and RVCE

iii. There would be a GCL guide and also RVCE guide for the projects

iv. The Projects would be selected based on the Industrial Viability for the project.

v. The Project would be concluded based on satisfactory achievement of the results or milestones and would be carried forward in case needed.

vi. On Specific Research / Product / Sub Systems Projects: While most of the resources would be used from GCL or RVCE; any specific investments would be mutually agreed and signed Off and milestones would be defined for achievement.

vii. viii. The Incubation Centres space would be provided by RVCE for the COEEM –Centre of Excellence for Electric Mobility.

ix. RCVE and the Interns should not work on any other similar projects during and post this engagement with GCL as per the terms of this MOU.

x. RCVE and the Interns shall not use the IPR and Confidential Information for any other projects or engagements.

MoU with University of Dortmund, Germany:

Objective is to have Students and faculty exchange program. One batch of 5 students and three professors visited RVCE during Jan-Feb 2019

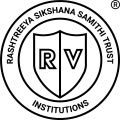

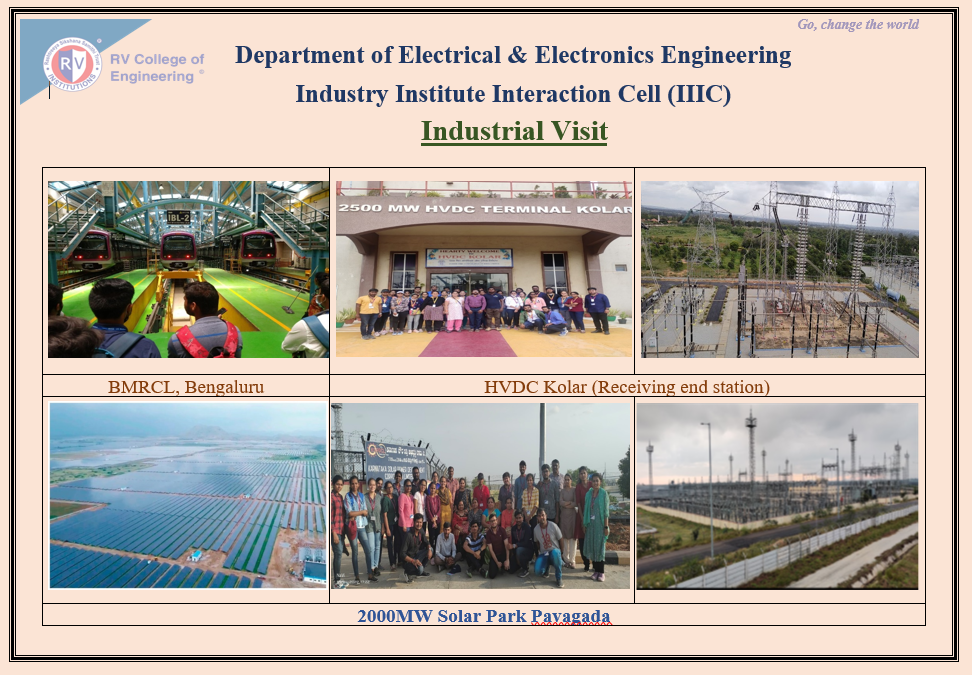

Industrial Visit

Objective :

-

Industrial visit is to provide students an insight regarding internal working of companies.

-

Industrial visit has its own importance in a career of a student who is pursuing a professional degree. It is considered as a part of college curriculum, mainly seen in Engineering.

-

It gives them exposure to current work practices as opposed to possibly theoretical knowledge being taught at college.

-

Industrial visits provide an excellent opportunity to interact with industries and know more about industrial environment.

-

Industrial visits are arranged by colleges to students with an objective of providing students functional opportunity in different sectors like IT, Manufacturing and services, finance and marketing.

-

Industrial visit helps to combine theoretical knowledge with industrial knowledge. Industrial realities are opened to the students through industrial visits.

Outcome:

-

Industry visits bridge the gap between theoretical training and practical learning in a real-life environment.

-

Industry visits provide opportunity for active/interactive learning experiences in-class as well outside the classroom environment.

-

With industry visits, students are able to better identify their prospective areas of work in the overall organizational function.

-

Industry visits help enhance interpersonal skills and communication techniques.

-

Students become more aware of industry practices and regulations during industry visits.

-

Industry visits broaden the outlook of students with exposure to different workforces from different industries.

Industrial Visits(2023-24)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

220 KV Sub-Station , Somanahalli, Bengaluru |

UG(5th Semester) |

31.01.24 |

|

2. |

220 KV Sub-Station , Somanahalli, Bengaluru |

UG(7th Semester) |

01.02.24 |

|

3. |

Agni Motors, Bengaluru |

UG(5th Semester) |

19.01.24 |

|

4. |

Mysore Electric Industries Limited |

UG(5th Semester) |

28.02.24 |

Industrial Visits(2022-23)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

400 KV Sub-Station , Nelamangala |

UG (7th Semester) |

12.01.23 |

|

2. |

Integrated Electric Company, Bengaluru |

UG (5th Semester) |

13.01.23 |

|

3. |

Varahi Hydro Plant and Adani Thermal Power Plant |

UG (5th Semester) |

27.02.23 |

|

4. |

Mysore Electric Company Limited , Bengalore |

UG (5th sem) Skill development program

|

17.07.23 |

|

6. |

Integrated Electric Company , Bengaluru |

UG (4th sem) Skill development program

|

18.07.23 |

Industrial Visits(2021-22)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

BMRCL, Bengaluru |

UG (6th sem) 73 |

27.05.22 |

Industrial Visits(2020-21)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

400 KV HVDC sub -station, Kolar |

PG (1st and 4th sem) 33 Students |

29.04.22 |

|

2. |

BMRCL, Bengaluru |

UG (6th sem) 73 Students |

27.05.22 |

|

3. |

2000 MW Solar power plant, Pavagada |

PG (1st and 4th sem) 33 Students |

31.05.22 |

Industrial Visits(2019-20)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

220KV receiving substation , Bangalore |

UG (5th sem) 78 |

16.10.19 & 30.10.19 |

|

2. |

400 KV receiving sub –station , Nelamangala |

UG (7th sem) 65 |

21.11.19 |

|

3. |

HVDC Power Transmission, Kolar |

PG (1st & 3rd sem) 32 |

07.12.19 |

|

4. |

JVS Electronics , Bidadi |

UG (7th sem) 65 |

21.11.19 |

|

5. |

Udupi Power Corporation, Varahi Linganamakki Dam , Sharavathi Valley Project, Varahi Under Ground Project, Hiriyur solar power plant and Chitradurga Wind Mill |

UG(7th sem) 71 |

23.12.2019 To 27.12.2019 |

Industrial Visits(2018-19)

|

Sl. No. |

Industry |

Target Group |

Date of Visit |

|

1. |

Integrated Electric Company , Bengaluru |

UG(5th sem) 65 |

05.10.2018 |

|

2. |

JVS Electronics , Bengaluru |

UG(7th sem) 62 |

09.10.2018 |

|

3. |

Udupi Power Corporation, Varahi Linganamakki Dam , Sharavathi Valley Project, Varahi Under Ground Project, Hiriyur solar power plant and Chitradurga Wind Mill |

UG(7th sem) 69 |

27.12.2018 To 30.12.2018 |

|

4. |

KAVIKA Transformer manufacturing Company, Bengaluru |

UG(4th sem) 74 |

25.02.2019 & 05.03.2019 |

|

5. |

Somanahalli 220KV receiving substation , Bangalore |

UG(6th sem) 65 |

27-02-2019 |

Industrial Visit Photos

Shimsha Solar Plant

ABB India Limited

Udupi Power Corporation Limited

Number of faculty from industrial representation from BOS

|

Sl. No. |

Name of the person |

Industry |

|

1 |

Dr. Sanjeev K Nayak EDU Manager

Email : sanjeev.nayak@valeo.com

|

Lighting Systems, APAC(SBSVTR001)

Bengaluru

|

|

2. |

Dr. Chandrasekhar Reddy Atla

Deputy General Manager,

Email: csreddy@prdcinfotech.com

|

Power Research and Development Consultants Pvt. Ltd.,

Bengaluru,

|

|

3. |

Sri. Prasad Ranga,

Email: prasad.ranga@flutech.in

|

The Chief Executive Officer,

Flutech Engineering Pvt. Ltd

Bengaluru

|

Papers Publications in association with Industry

|

SL.NO |

Title |

Author |

|

1. |

A Novel Predictive DSM Strategy to Match Power Outage Pattern for Optimal Cost with Solar and Diesel Power |

Electrical & Electronics Engineering RV College of Engineering.

Technical Advisor Spectrum Consultants Bangalore, India. |

|

2. |

Optimisation of Stand-Alone Solar Plant with GUI Support |

Electrical & Electronics Engineering RV College of Engineering.

Technical Advisor Spectrum Consultants Bangalore, India |

|

3. |

Protection challenges with Penetration of Renewable Energy Resources in Power System |

Electrical & Electronics Engineering RV College of Engineering.

CPRI, Bangalore. |

|

4. |

Enhanced Real Time Coordination of Distance and User Defined Over Current Relays |

Electrical & Electronics Engineering RV College of Engineering.

CPRI, Bangalore. |

|

5. |

Adaptive Protection Coordination Scheme for Power Networks under Penetration of DER |

Electrical & Electronics Engineering RV College of Engineering.

CPRI, Bangalore. |

|

6. |

Dynamic Stability Enhancement of Power System using Fuzzy Power System |

Electrical & Electronics Engineering RV College of Engineering.

CPRI, Bangalore. |

|

7. |

Design and Analysis of Fly Back Converter for Grid & Filament Power Supplies of Travelling Wave Tube. |

Electrical & Electronics Engineering RV College of Engineering.

ADA, Bangalore. |

|

8. |

Novel Techniques for Improvements in Sequential Switching Shunt Regulator for Spacecraft. |

Electrical & Electronics Engineering RV College of Engineering.

ISRO, Bangalore |

|

9. |

Evaluation of Adaptive and Conventional Distance Relay for Parallel Transmission Line with Mutual Coupling. |

Electrical & Electronics Engineering RV College of Engineering.

Centum, Bangalore |

Professional Societies