Interdisciplinary Research Center

|

PECVD Cluster Tool: CT-100 System 5 Individual Process chambers are connected to central transfer chamber. To Grow Dielectrics, Passivation Layers, Doped a-Si Layers, SiO2, Si3N4, DLC, and other films

|

|

|

Solar Metalization Unit: Sputter Coater Used for Sequential deposition of Metals, Transparent conducting oxides & Dielectrics. |

|

|

Box Coater: Thermal & E-beam Evaporation Deposits both metals and oxide materials, including aluminum, chromium , gold, indium, and many others Deposit metallic contact layers for thin film devices such as OLEDs, solar cells and thin-film transistors. |

|

|

Cathode Arc Evaporation sytem To deposit extremely hard films to protect the surface of cutting tools and extended their life significantly. |

|

|

DUAL COATING SYSTEM: Solar Thermal Absorbers Custom Designed DC Magnetron Sputtering & PECVD Coating System for Solar thermal receiver tubes

|

|

|

Plasma Deposition system To grow carbon at low temperatures |

|

|

Litography Unit Sonoplotter and Laser Writer Picoliter fluid dispensing system that uses controlled ultrasonics to deposit fluid in a noncontact manner for the microarray and polymer electronics markets. Mask less Lithography Micro Device pattern generation up to 0.9um resolution.

|

|

|

Nano-Fiber Electrospinning Unit used to make nano and micro fibers ranging from 50nm to 5 microns in diameter Many kind of polymers like Protein nanofibers, carbon nanotubes, inorganic nanofibers etc. |

|

|

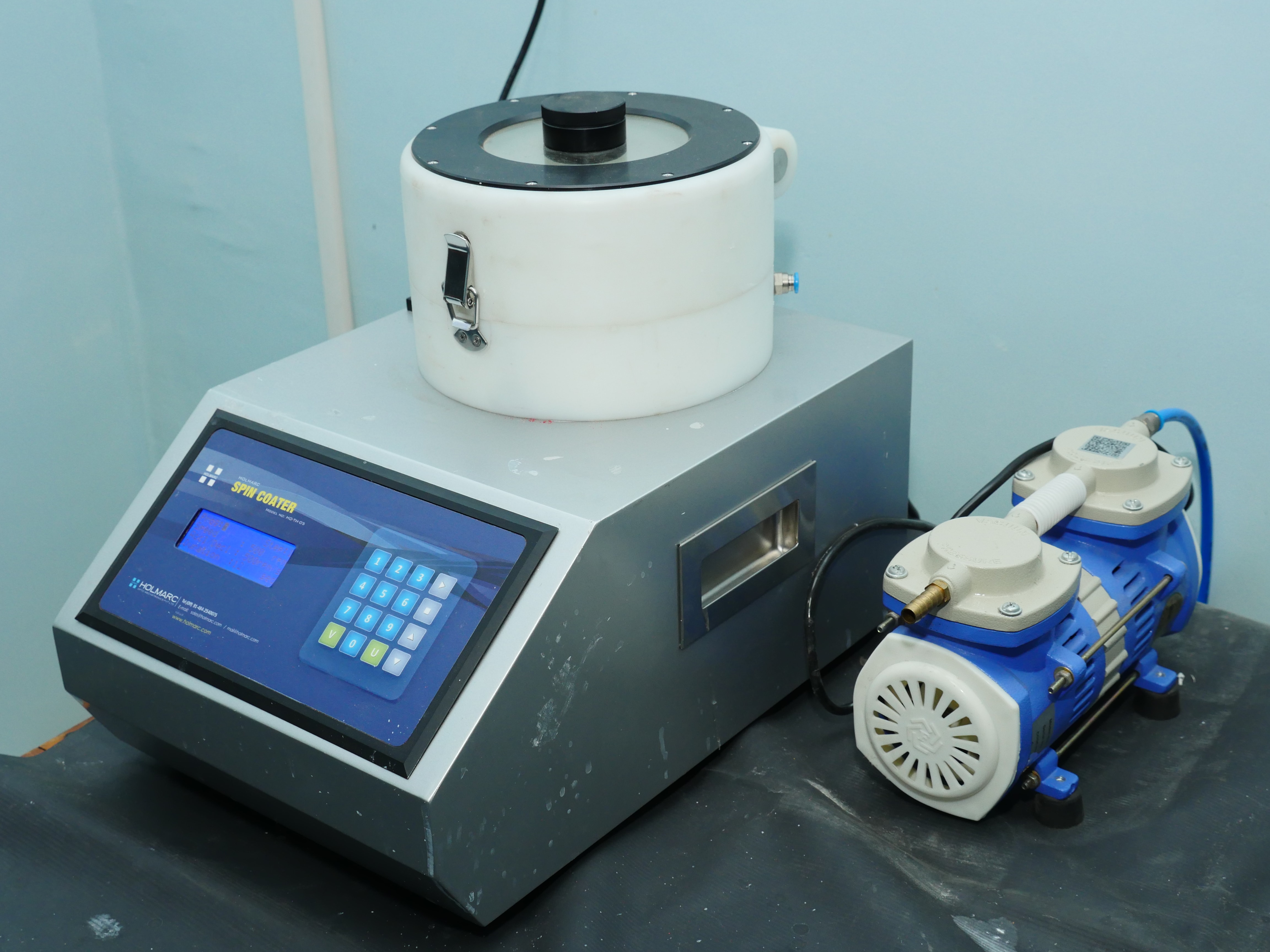

Spin Coater Spin Coaters are ideal for depositing photoresists, polymides, metal-organics, dopants, sillica films and most organic and aqueous solutions to planar substrates |

|

|

Microwave Furnace Maximum temperature of 1600⁰C for anealing process |

|

|

Tubular Furnace Maximum temperature of 1200⁰C for anealing process |

|

|

Bench Top Sputtering Unit To deposit Conducting electrodes on substrates |

|